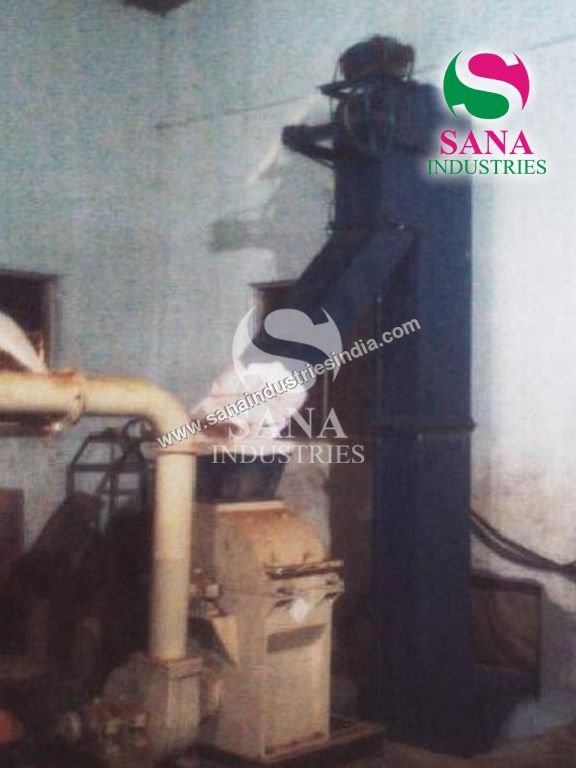

Material Lifting And Powders Conveying Machinery

Price 200000 INR/ Piece

Material Lifting And Powders Conveying Machinery Specification

- Frequency

- 50/60 Hz

- Noise Level

- Low (<75 dB)

- Operating Temperature

- Up To 60C

- Phase

- Three Phase

- Function Type

- Conveying And Lifting

- Features

- Sealed Transfer, Easy Dismantling

- Automation Grade

- Automatic

- Speed Mode

- Variable (VFD Controlled)

- Machine Type

- Material Loader/Conveyor

- Power Source

- Electric

- Feeding System

- Auger/Screw Feeding

- Product Type

- Powder Conveying Equipment

- General Use

- Powder Feeding And Lifting In Food & Pharmaceutical Industries

- Material

- Stainless Steel

- Type

- Screw Conveyor System

- Weight (kg)

- Approx 250 Kg

- Product Shape

- Rectangular Hopper With Vertical Tube

- Computerized

- No

- Automatic

- Yes

- Control System

- PLC Based

- Installation Type

- Floor Mounted

- Voltage

- 415V

- Power

- 2 HP

- Dimension (L*W*H)

- Customized

- Raw Material

- Stainless Steel, Mild Steel

- Color

- Silver & Blue

About Material Lifting And Powders Conveying Machinery

We are counted amongst as the foremost manufactures and suppliers of superior quality Materials Lifting and Powders Conveying Machinery. This machinery is manufactured in compliance with international quality standards. Subjected to stringent quality tests under the supervision of our quality controllers, this machinery is extensively demanded in the industry. Further, this Materials Lifting and Powders Conveying Machinery are known for its features like excellent performance, durable finish standards and longer service life.

Specifications:

- Bucket Elevators used for Raw Spices and powders mainly raw materials

- Screw Conveyors used for grounding powders to another place or into other machinery

- Capacities will be adjusted at the time of installation. The power required 2 HP

Efficient and Automated Powder Handling

Our Screw Conveyor System features a sealed, easy-to-clean design tailored for the safe movement of powders. Operating automatically with PLC controls, it maintains precise operational performance while simplifying handling and increasing productivity in food and pharmaceutical applications.

Customizable for Versatile Applications

Built from robust stainless or mild steel, the conveyor system accommodates specific size requirements and layout preferences. Its variable speed, adjustable power, and floor-mounted setup allow seamless integration into diverse production workflows, supporting both large and small-scale operations.

FAQs of Material Lifting And Powders Conveying Machinery:

Q: How does the screw conveyor system operate for powder lifting and conveying?

A: The screw conveyor system utilizes an auger or screw mechanism inside a sealed tube to transport powders from a rectangular hopper vertically or horizontally. The automated operation is managed via PLC controls, ensuring consistent flow and minimal material loss.Q: What materials can be transported with this machinery?

A: This equipment is suitable for conveying a variety of powders used within the food and pharmaceutical industries, thanks to its corrosion-resistant stainless steel construction and sealed transfer design.Q: When should you use variable speed mode in this system?

A: Variable speed mode, controlled by the integrated VFD, allows operators to adjust conveying speeds according to material type and production requirements, optimizing process efficiency and minimizing spillage.Q: Where is the ideal installation location for this machine?

A: The floor-mounted design is compatible with most industrial settings; typically, it should be installed near mixing or processing points where powder input and discharge are conveniently aligned with existing production lines.Q: What are the key benefits of using a PLC-based automatic control system?

A: PLC-based control ensures consistent operation, safety interlocking, and process repeatability. Automation reduces manual intervention, helping achieve higher throughput, greater accuracy, and lower operational risks.Q: How is the machinery maintained, and is it easy to clean?

A: Maintenance is simplified by the systems easy dismantling design. The sealed construction minimizes residue build-up, making regular cleaning straightforward, especially with stainless steel components suited for hygienic applications.

Price:

- 50

- 100

- 200

- 250

- 500

- 1000+

More Products in Material Carrying Machinery Category

Bucket Elevator

Price 45000 INR / Piece

Minimum Order Quantity : 1 Piece

Noise Level : Low

Raw Material : Other, Bulk solid materials

Voltage : 220240 V

Automatic : Yes

GST : 36ARBPS2525A1Z8

|

SANA INDUSTRIES

All Rights Reserved.(Terms of Use) Developed and Managed by Infocom Network Private Limited. |

Send Inquiry

Send Inquiry